In the competitive landscape of edible oils, maintaining stringent quality control protocols is essential to guarantee product safety, nutritional value, and consumer trust. Sunflower seed oil, prized for its light flavor and health benefits, demands an exacting production process. This article delves into the critical quality control checkpoints in sunflower seed oil manufacturing, with a sharp focus on the application of HACCP (Hazard Analysis and Critical Control Points) and the ISO 22000 food safety management system, ensuring comprehensive compliance and enhanced market confidence.

Quality control begins with rigorous raw material assessment. Cleanliness and seed integrity are paramount; contaminants or damaged seeds can introduce rancidity or off-flavors, compromising oil stability and shelf life.

Typical cleaning stages involve multi-level sieving and air aspiration to eliminate dust, stones, and plant debris, achieving seed purity levels above 99.5%. Following cleaning, precision de-hulling technologies remove seed shells without damaging kernels, as hull remnants adversely affect oil clarity and taste.

Choosing the appropriate pressing method profoundly impacts oil quality metrics such as free fatty acid content, color, and antioxidant retention.

| Pressing Method | Advantages | Challenges |

|---|---|---|

| Cold Pressing | Preserves antioxidants & vitamins; less heat damage; premium oil quality | Lower yield (~80-85%); higher production costs |

| Hot Pressing | Higher extraction efficiency (~90-95%); cost-effective for large scale | Potential nutrient degradation; requires downstream refining |

Industry norms indicate that cold pressing oils show 30-40% higher polyphenol retention, enhancing antioxidative properties. Selecting the pressing method should align with target markets and product positioning.

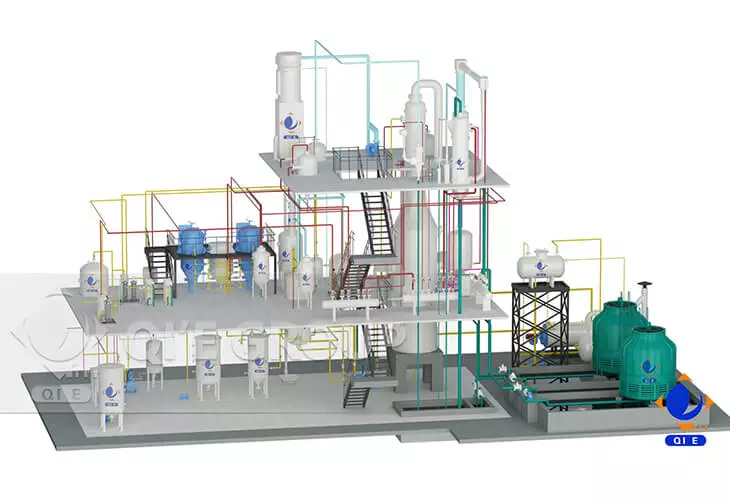

Post-pressing, filtration removes suspended solids to enhance oil clarity and stability. Employing a high-efficiency multi-stage filtration system, incorporating technologies like automatic backwash filters, minimizes downtime while maintaining filtration precision down to 5 microns.

Refining steps typically include degumming, neutralization, bleaching, and deodorization. Precise control of temperature and chemical dosing reduces nutrient loss and residual contaminants. For example, refining conditions capped below 250 °C during deodorization maximize retention of tocopherols and minimize trans-fat formation.

Modern sunflower seed oil production emphasizes hygienic packaging to prevent microbial contamination and oxidative degradation. Employing aseptic filling technology within ISO 22000-compliant clean rooms safeguards oil integrity and prolongs shelf life up to 12-18 months under recommended storage.

Automated filling lines equipped with sterile nozzles and controlled atmosphere flushing reduce oxygen exposure, critical for sensitive oils. This mechanism aligns with HACCP principles by controlling contamination risk at the final critical control point.

The integration of HACCP and ISO 22000 frameworks establishes a robust food safety management system, crucial for compliance with international export regulations and consumer safety demands.

In sunflower seed oil production, HACCP identifies critical control points (CCPs) such as:

ISO 22000 facilitates systematic management through documentation, monitoring, and continuous improvement. By adhering to its clauses, manufacturers can achieve transparent traceability and quick response to potential hazards.

Producers frequently encounter issues like fluctuating seed quality, inconsistent pressing yields, or filtration clogging. Expert technicians recommend:

Engineers highlight that introducing these measures can increase extraction efficiency by 10% and reduce downtime by up to 25%, significantly improving profitability while maintaining superior oil standards.