Sunflower oil is a prized edible oil widely appreciated for its light flavor and high nutritional value, especially its rich linoleic acid content. However, maintaining the oil’s quality throughout production remains a significant challenge due to its susceptibility to oxidation and contamination. This article meticulously explores the critical control points in the sunflower oil production chain—from raw material cleaning to packaging—and proposes targeted preventive measures. By aligning with internationally recognized food safety standards such as HACCP and ISO 22000, and incorporating frontline technical expertise, oil manufacturers can establish a robust quality control system that safeguards product stability, enhances safety, and drives market competitiveness.

The journey to premium sunflower oil begins with thorough cleaning of the seeds. Effective removal of foreign matter and impurities—dust, stones, husks—is essential to reduce microbial load and unwanted enzymatic activity which accelerate acidification. Industry benchmarks recommend cleaning efficiency above 98%, verified through moisture and impurity content testing, e.g., moisture under 8%, contaminants below 0.5%.

Advanced screening and aspiration systems combined with magnetic separators ensure removal of metallic and physical contaminants. Maintaining seed integrity at this stage not only improves pressing yields but also minimizes post-extraction refining burden.

Dehulling—or seed shell removal—is critical for limiting fiber and phenol compounds which can induce off-flavors and increase acid values during storage. Mechanical abrasion or impact dehullers that achieve over 90% hull removal without kernel damage are preferred. Optimized dehulling balances improved free-oil extraction and reduced solvent refining, directly influencing the organoleptic properties and shelf stability of the oil.

The pressing stage predominantly determines sunflower oil’s nutritional profile and sensory qualities. Cold pressing, conducted below 50°C, preserves heat-sensitive polyunsaturated fatty acids and vitamin E content, yielding oil with excellent color and aroma but slightly lower volume (~85% extraction efficiency). Hot pressing (up to 110°C) increases yield (>90%) by softening kernels but risks partial denaturation of nutrients and increased free fatty acid (FFA) levels.

Producers often select pressing parameters based on market product positioning—premium health oil favors cold pressing while mass-market oil utilizes hot pressing balanced by advanced refining steps.

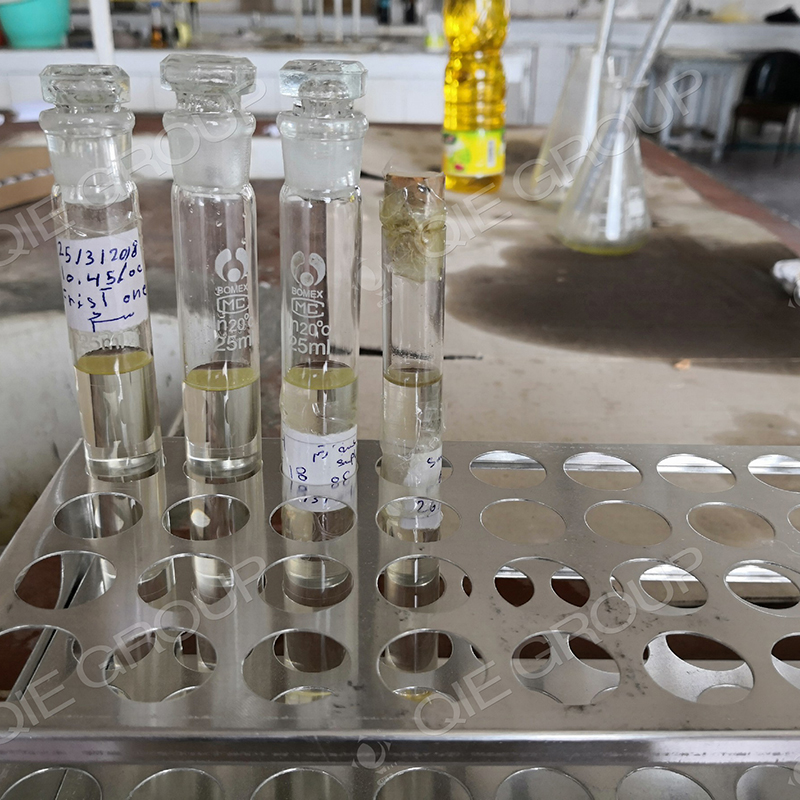

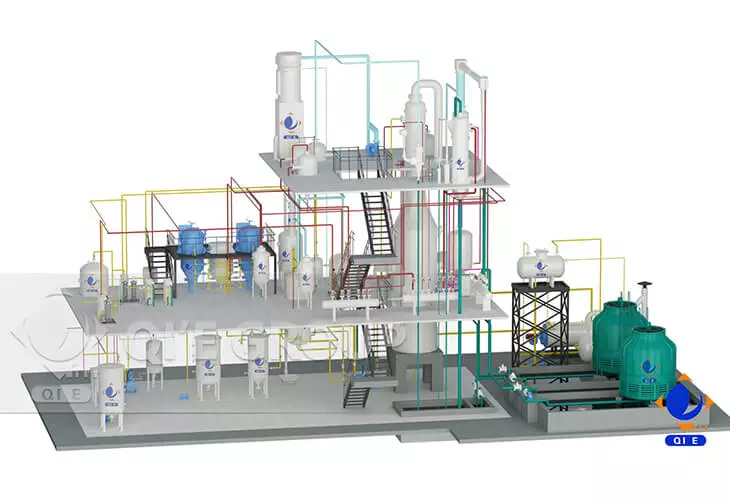

Filtration serves as a crucial barrier against particulates, residual solids, and microbial contaminants, thus directly impacting oil clarity and oxidative stability. Current best practices advocate multi-stage filtration—initial coarse filtration followed by fine filtration—using food-grade filtration media compliant with FDA and EU regulations.

Innovative equipment featuring automatic backwash filter cartridges significantly reduce downtime and labor costs while maintaining consistent filtration efficiency above 99.8%. This technology facilitates continuous cleaning without interrupting production flow, effectively preventing membrane fouling and extending filter lifespan.

Figure 1 illustrates a typical food-grade filtration workflow integrating automatic backwashing technology in sunflower oil processing.

Refining is indispensable to eliminate undesirable flavors, odors, and contaminants such as phospholipids and free fatty acids that cause sensory degradation and reduced shelf life. Vacuum deodorization under controlled temperature (180–220°C) efficiently removes volatile compounds while minimizing thermal oxidation.

Implementing a multi-stage refining line aligned with ISO 22000 ensures consistent product quality and compliance with food safety protocols. Data from industry case studies show that oils refined through vacuum deodorization exhibit up to 40% lower peroxide values and a significant reduction in off-flavors.

The final step involves aseptic filling using sterile air and food-grade packaging materials to prevent post-production microbial contamination and oxidation. Stainless steel or multilayer PET bottles with oxygen barrier layers are recommended. Packaging environments meeting GMP standards coupled with nitrogen flushing prolong the oil’s shelf life to beyond 12 months without additive preservatives.

Integration of inline quality sensors detecting turbidity and moisture content in filling stations provides an additional process control layer, advancing product consistency.

Integrating advanced filtration systems with automatic backwash filters is a pivotal upgrade for sunflower oil producers aiming for uncompromising quality control. These systems reduce manual cleaning efforts by over 70% and maintain stable oil turbidity below 5 NTU, directly translating into superior shelf life and customer satisfaction.

Choosing food-grade filtration equipment certified under FDA and EU norms also strengthens compliance documentation vital for international export markets, reinforcing corporate reputation and opening channels for premium contracts.