How to Increase Sunflower Oil Yield: Cold Press vs Hot Press Comparison and Practical Optimization Tips

2025-10-23

Application Tips

This article systematically analyzes the six core stages of sunflower oil production—from seed cleaning and dehulling to pressing, filtration, refining, and packaging—highlighting how each step contributes to maximizing oil yield and quality. It provides a detailed comparison between cold press and hot press technologies, examining their impact on oil extraction efficiency and sensory properties. Real-world factory case studies demonstrate measurable improvements in yield through optimized parameters and maintenance practices. Practical tips, common pitfalls, and multi-scenario applications (food-grade vs industrial-grade) are covered to support small-to-medium enterprises in upgrading their production lines effectively. Suitable for decision-makers in edible oil manufacturing seeking technical guidance and SEO-friendly insights.

How to Boost Sunflower Oil Yield: Cold Press vs Hot Press – Real-World Optimization Tips for Small & Medium Mills

For small and medium-scale sunflower oil producers, every percentage point in yield matters—not just for profit margins, but also for competitiveness in global B2B markets. According to industry benchmarks from the International Oleochemical Society (IOS), optimizing processing steps can increase oil extraction by up to 8–12% without major capital investment.

The 6 Core Steps That Make or Break Your Yield

From raw seed intake to final packaging, each stage must be tightly controlled:

- Seed Cleaning & Dehulling: Removes dust, stones, and shells—critical for reducing machine wear and improving press efficiency.

- Preheating (Hot Press Only): Raises temperature to ~70°C to soften oil bodies and enhance flow.

- Pressing: Either cold-pressed (≤40°C) or hot-pressed (60–85°C), depending on quality needs.

- Filtration: Removes solids using plate-and-frame filters or centrifugal separators.

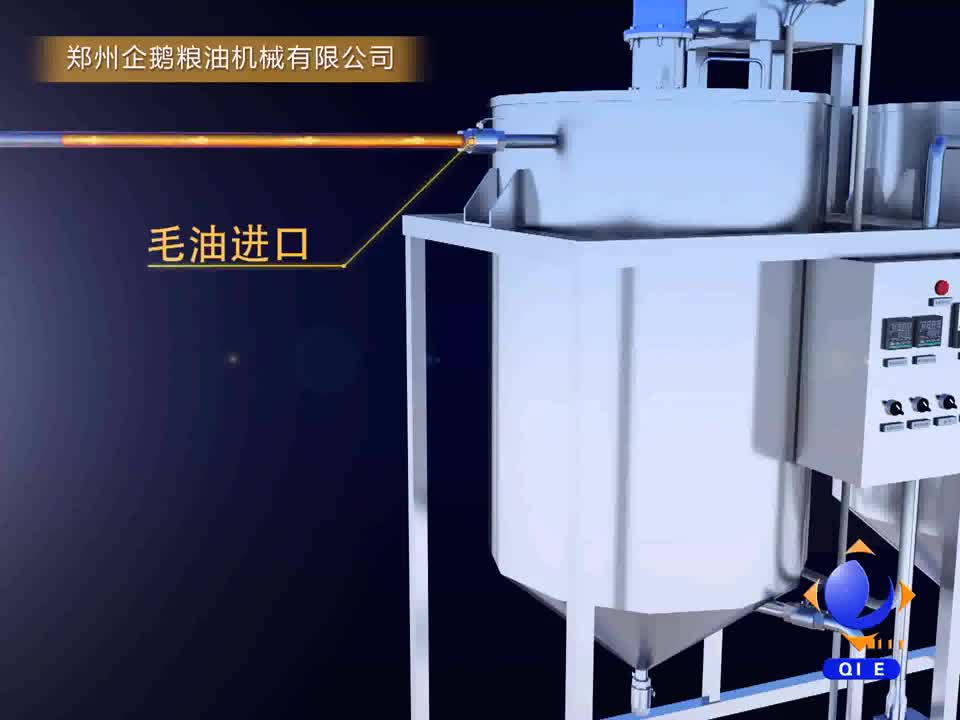

- Refining: Destoned, bleached, and deodorized to meet food-grade standards (e.g., ISO 22000).

- Packaging: Airtight containers prevent oxidation—key for shelf life and export compliance.

Cold Press vs Hot Press: What’s Best for Your Market?

| Parameter |

Cold Press |

Hot Press |

| Avg. Yield (%) |

32–35% |

38–42% |

| Oil Quality |

High in antioxidants, mild flavor |

Lower natural nutrients, neutral taste |

| Energy Use |

Low |

Moderate to High |

In a case study from a Ukrainian mill upgrading from batch hot pressing to continuous screw press with pre-heating control, yields rose from 36% to 41% within three months—while maintaining ISO 22000 compliance. The key? Consistent moisture content (6–8%) and proper shell removal before pressing.

Avoid These Common Mistakes

Many small mills lose 3–5% yield due to:

- Overloading presses—leading to uneven pressure distribution

- Using uncalibrated moisture meters—causing poor seed prep

- Skipping regular filter cleaning—a common cause of clogging and reduced throughput

If you're looking to scale your operation or improve consistency, our team has helped over 50+ clients achieve measurable gains through process audits and equipment optimization. Whether you’re targeting European food-grade buyers or industrial users in Asia, the right setup makes all the difference.

Want to See It Live?

Join our monthly technical webinar where we walk through real-time data from working plants—including how one Moroccan producer boosted yield by 9% in under 60 days. Watch full video tutorials and download our free “Sunflower Oil Process Checklist”.

Watch Now – Free Access for B2B Buyers