Sunflower oil is a popular cooking oil known for its health - promoting properties and pleasant taste. However, ensuring its high - quality standards requires a comprehensive quality control process. This article will systematically analyze the entire process of sunflower oil quality control, aiming to help production managers establish a perfect quality management system.

The quality control of sunflower oil starts from the raw materials. The cleanliness of sunflower seeds is crucial as they may be contaminated with various impurities and metals during harvesting and transportation. Seed cleaners and de - shellers play a vital role in this stage. A high - quality seed cleaner can remove up to 95% of impurities such as dust, stones, and broken seeds. For example, the advanced seed cleaners in our company are designed with high - precision sieving mechanisms, which can effectively separate impurities based on size and density differences.

De - shelling is another important step. By removing the sunflower seed shells, we can reduce the risk of introducing additional contaminants and improve the quality of the final product. Our de - shellers are equipped with sharp blades and advanced control systems, which can achieve a de - shelling rate of over 90%, ensuring that most of the shells are removed without damaging the kernels.

There are two main pressing technologies for sunflower oil: cold - pressing and hot - pressing. Cold - pressing is carried out at a relatively low temperature (usually below 60°C), which can preserve more nutrients in the oil, such as vitamin E and unsaturated fatty acids. According to research, cold - pressed sunflower oil can retain up to 80% of the original vitamin E content in sunflower seeds. However, the oil yield of cold - pressing is relatively low, usually around 25% - 30%.

On the other hand, hot - pressing is performed at a higher temperature (around 120 - 180°C), which can significantly increase the oil yield to 35% - 40%. But it also increases the risk of oxidation, as high temperatures can accelerate the reaction between oil and oxygen. Our engineers recommend using cold - pressing for high - end products that emphasize nutrition, while hot - pressing can be considered for mass - produced products with a lower price - sensitivity.

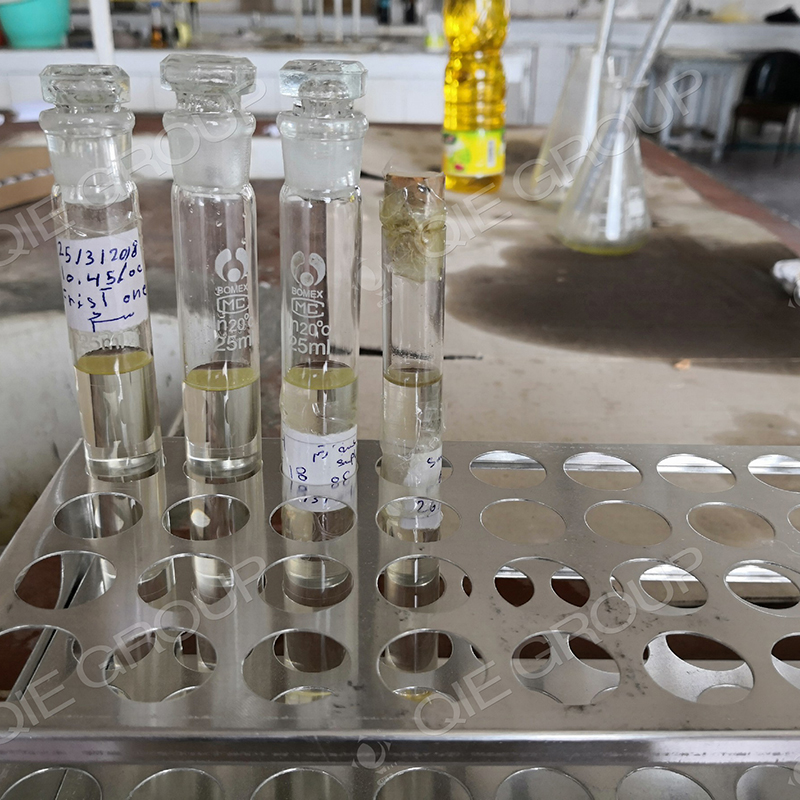

After pressing, the crude sunflower oil needs to go through filtration and refining processes to remove solid particles, odors, and free fatty acids. Filter presses are used to remove large - sized solid particles. High - quality filter presses can reduce the solid particle content in the oil to less than 0.1%. Our company's filter presses are made of food - grade materials and are designed with a multi - layer filtration system, which can effectively ensure the purity of the oil.

Refining is a more complex process that involves removing free fatty acids, pigments, and odors. According to HACCP and ISO 22000 food safety standards, the free fatty acid content in refined sunflower oil should be less than 0.1%. Our refining machines use advanced technologies such as magnetic separators and vacuum de - odorization. Magnetic separators can effectively remove metal residues, while vacuum de - odorization can remove unpleasant odors without affecting the nutritional value of the oil.

The final step in the sunflower oil production process is filling and packaging. Aseptic filling technology is essential to ensure product hygiene and extend the shelf - life. Aseptic filling can prevent the entry of bacteria and oxygen, reducing the risk of oxidation and spoilage. Our aseptic filling machines are designed with strict sterilization procedures and air - tight filling systems, which can ensure that the sunflower oil remains fresh and high - quality for a long time.

In conclusion, the quality control of sunflower oil is a comprehensive process that requires strict management at each stage. Our company's advanced technologies and equipment can provide you with reliable solutions to ensure that your sunflower oil products meet high - quality standards. If you are looking for professional sunflower oil quality control solutions, click here to learn more about our products and services.