In the global edible oil market, sunflower oil holds a significant share due to its high nutritional value and wide range of applications. Ensuring the quality of sunflower oil throughout the production process is crucial for producers to gain a competitive edge. This article provides a comprehensive guide to quality control in sunflower oil processing, focusing on key techniques and equipment.

The quality of sunflower seeds directly affects the final product. Before the production process, seeds need to be thoroughly cleaned to remove impurities such as soil, stones, and broken seeds. Studies show that effective seed cleaning can reduce the impurity content in the oil by up to 30%. Hulling is another important step. Removing the hulls can prevent the introduction of unnecessary fibers and shells into the oil, improving the clarity and purity of the final product. For example, in a large - scale sunflower oil production plant, after proper hulling, the oil's initial clarity can be increased by about 20%.

There are different types of mechanical pressing methods, including cold - pressing and hot - pressing. Cold - pressing can retain more nutrients in the sunflower oil, such as vitamin E and unsaturated fatty acids. In cold - pressing, the temperature is usually controlled below 60°C, which can preserve up to 90% of the original nutrients. Hot - pressing, on the other hand, can achieve a higher oil yield. By adjusting the pressing temperature and pressure, the oil yield can reach up to 45% - 50%. However, it may cause some nutrient loss.

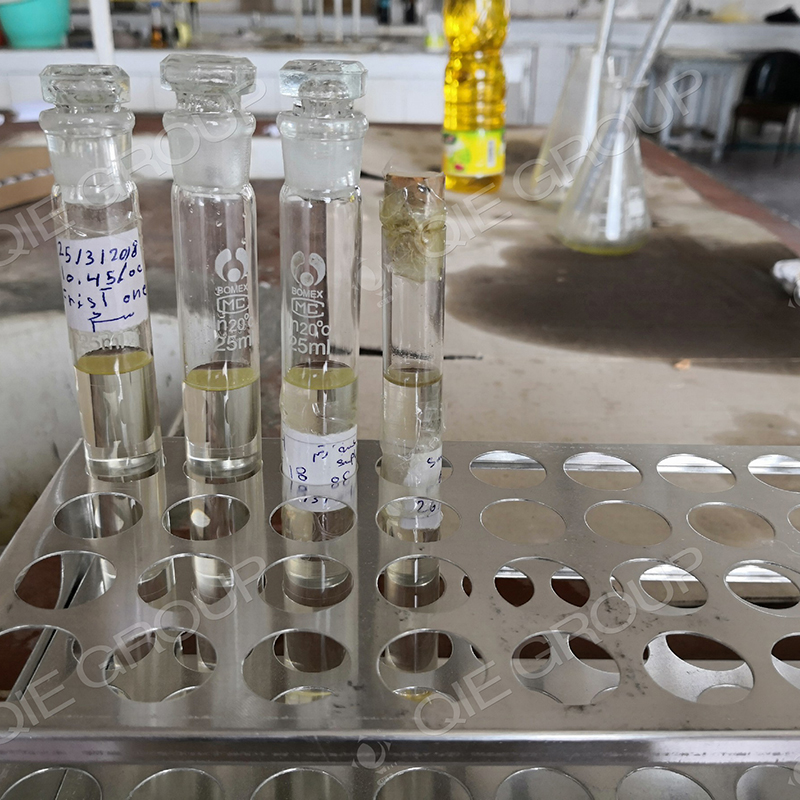

Filtration is a critical step in ensuring the quality of sunflower oil. The filtration process can remove impurities, such as iron filings, residues, and some fine particles. To improve filtration precision, advanced filtration equipment is necessary. For example, the automatic back - washing filter element system can significantly enhance filtration efficiency. It can filter particles as small as 1 - 5 microns, reducing the impurity content in the oil to less than 0.1%. This system can also automatically clean the filter element, reducing manual labor and downtime.

The refining process includes degumming, deacidification, decolorization, and deodorization. Degumming can remove phospholipids in the oil, which can prevent the oil from oxidizing and deteriorating. Deacidification can reduce the acid value of the oil, improving its stability. Decolorization can remove pigments in the oil, making the oil more transparent. Deodorization can remove unpleasant odors, enhancing the sensory quality of the oil. After a complete refining process, the acid value of the oil can be reduced to less than 0.1mg KOH/g, and the peroxide value can be controlled below 5meq/kg.

Aseptic filling technology is essential for ensuring the long - term quality of sunflower oil. By using aseptic filling equipment, the oil can be filled into containers in a sterile environment, preventing microbial contamination. This technology can extend the shelf - life of sunflower oil by up to 6 - 12 months. In addition, proper packaging materials, such as dark glass bottles or high - quality plastic containers, can also protect the oil from light and oxygen, further reducing the risk of oxidation.

In conclusion, by implementing strict quality control measures in each step of sunflower oil production, from raw material cleaning to filling and packaging, producers can ensure the high quality and stability of their products. To learn more about advanced equipment and technologies for sunflower oil processing, click here.