The quality and compliance of sunflower seed oil heavily depend on the efficiency of impurity removal during processing. For exporters targeting international markets, ensuring the final product meets stringent food-grade standards is non-negotiable. This article meticulously dissects the complete processing workflow—from cleaning and dehulling to pressing and filtration—offering practical solutions to boost oil purity, optimize yield rates of 35%-50%, and achieve energy-efficient production.

Impurities such as dust, dirt, and broken seed fragments compromise sunflower oil’s color, stability, and overall quality — factors closely monitored in export regulations. Effective cleaning equipment selection is key. Opting for advanced rotary drum cleaners that combine sieving and aspiration can remove up to 98% of surface contaminants before further processing.

Operators should pay special attention to moisture levels, as overly wet seeds increase the chance of microbial growth, affecting oil quality. Maintaining seed moisture below 8% post-cleaning ensures better oil stability down the line.

The presence of residual hard shells drastically lowers pressing efficiency and increases wear on equipment. High-performance dehullers, such as centrifugal or roller-type machines tailored for sunflower seeds, can reduce shell content by more than 90%. This step is pivotal not only for yield enhancement but also for preventing bitter-tasting phenolics from contaminating the oil.

Common troubleshooting involves monitoring for improper seed feed, which leads to incomplete hull removal. Implementing automatic seed feeders and real-time shell content analyzers can mitigate these issues effectively.

| Feature | Screw Press | Hydraulic Press |

|---|---|---|

| Oil Yield | 35%-45% | 40%-50% |

| Production Rate | High (continuous) | Moderate (batch) |

| Energy Consumption | Lower | Higher |

| Automation Level | Available (semi-auto to full-auto) | Limited (mostly manual) |

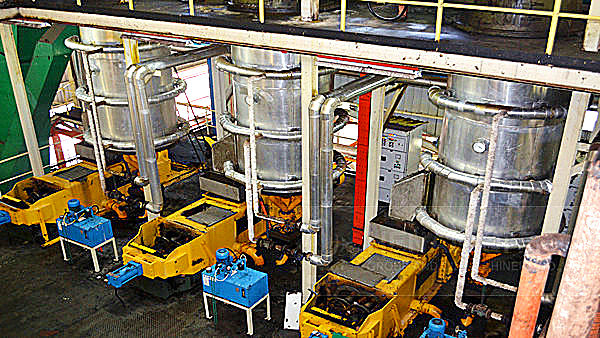

Selecting the correct pressing technology hinges on production scale and desired efficiency. Full-automatic screw presses enhance throughput and minimize labor costs, ideal for medium-to-large operations, whereas hydraulic presses suit small-scale batches focused on maximum oil extraction.

Filtration removes tiny particulates that cloud oil clarity and reduce shelf-life. Physical filtration systems employing mesh filters handle coarse solids, while precision filter cartridges trap microscopic impurities and residual moisture, critical for export-grade oils.

Quality control managers should incorporate regular transparency and turbidity testing using spectrophotometers, confirming oil clarity meets standards such as an absorbance level below 0.05 at 420 nm wavelength.

Consider a small oil factory that recently integrated a semi-automatic screw press alongside advanced dehulling and multi-stage filtration systems. They reported a 15% increase in oil yield and reduced impurities leading to higher export order volumes within six months. Their energy consumption also decreased by nearly 20%, showcasing the operational and financial benefits of strategic equipment upgrades.

Mastering these critical details empowers your sunflower seed oil to confidently meet and exceed international export standards — making your product a trusted choice in the global market.