In the global market, sunflower oil is a highly sought - after commodity. Understanding its processing flow is crucial for both production managers and front - line operators. This report will delve into the entire process of sunflower oil processing, from seed cleaning to filtration.

The first step in sunflower oil processing is seed cleaning. The seeds may contain various impurities such as dust, stones, and broken seeds. By using advanced cleaning equipment, the purity of the seeds can be significantly improved. For example, through screening and air - separation techniques, up to 95% of impurities can be removed. This not only enhances the raw material purity but also lays a solid foundation for subsequent processes.

After cleaning, the seeds need to be dehulled. Dehulling is essential as the hulls contain little oil and can affect the quality and yield of the final product. Modern dehulling machines can efficiently remove the hulls while minimizing seed damage. The dehulling efficiency can reach up to 90%, which directly contributes to an increase in the oil - bearing rate of the seeds.

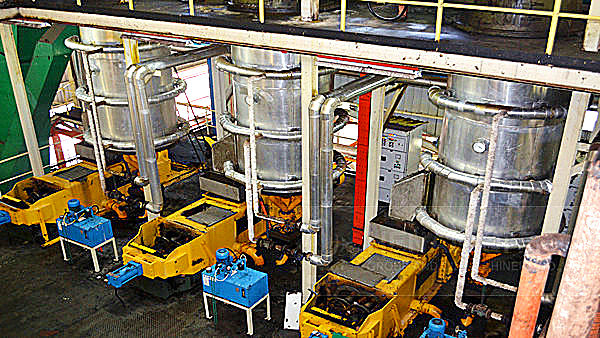

Pressing is the core step in sunflower oil production. There are different pressing techniques, including cold - pressing and hot - pressing. Cold - pressing can preserve more nutrients in the oil but has a relatively lower oil yield, usually around 30% - 35%. Hot - pressing, on the other hand, can increase the oil yield to 40% - 45% but may cause some nutrient loss. The choice of pressing method depends on the market demand and production goals.

The degree of automation of the oil - pressing equipment also has a significant impact on production efficiency and cost. Fully automated equipment can reduce labor costs by up to 50% and increase production efficiency by 30% compared to semi - automated or manual equipment.

After pressing, the crude oil needs to be filtered to remove impurities such as solid particles and gum. Filtration techniques, such as plate - and - frame filtration and membrane filtration, can effectively improve the clarity and quality of the oil. High - precision filtration can remove up to 99% of impurities, ensuring that the final product meets market quality requirements.

Each processing stage has a direct impact on the quality and yield of sunflower oil. For example, poor seed cleaning can lead to a higher impurity content in the oil, affecting its flavor and shelf - life. Inadequate dehulling can reduce the oil - bearing rate, resulting in lower yields. And improper pressing and filtration can lead to a decrease in oil quality.

In actual production, operators may encounter various problems. Here are some practical solutions:

One of the main pain points in the sunflower oil industry is the balance between production efficiency and product quality. To address this, enterprises can adopt advanced automated equipment and standardized production processes. By using fully automated production lines, the production efficiency can be improved while ensuring consistent product quality.

For more in - depth technical knowledge and industry insights, we invite you to follow our technical column. Stay updated with the latest trends and solutions in the sunflower oil processing industry.