Selecting the right sunflower oil screw press for factories of different scales is a crucial decision that can significantly impact production efficiency, cost, and overall business success. This guide will delve into the equipment configuration logic for sunflower oil screw presses from four major process steps: cleaning, shelling, pressing, and filtering. By analyzing the actual application scenarios of users with different scales, we aim to provide a targeted selection guide to help users match their production capacity requirements with technical parameters.

For small-scale processing plants, such as small workshops, the focus is on low-cost, easy-to-operate, and semi-automatic models. These machines offer several advantages. Firstly, they require less manual intervention. Workers only need to perform simple operations at key points, which reduces labor costs. Secondly, they are easy to maintain. With fewer complex components, the maintenance process is straightforward, and the maintenance cost is relatively low.

For example, a small semi-automatic sunflower oil screw press can achieve an oil output rate of about 35% - 40%. The energy consumption is relatively low, usually around 10 - 15 kWh per day. These machines are often made of common materials but still ensure basic performance and quality. The simple structure also makes it easy for operators to understand and operate.

Medium-scale processing plants need to balance efficiency and stability. A medium-automation level + modular design of the pressing system is recommended. The modular design allows for easy expansion and adjustment according to production needs. It can also improve the overall stability of the system.

These presses usually have a medium automation level, which means they can complete most of the processing steps automatically, but still allow some manual adjustment when necessary. The oil output rate can reach 40% - 45%. The energy consumption is around 20 - 30 kWh per day. The use of high-quality materials, such as stainless steel, can ensure the hygiene and safety of the production process. For example, the stainless steel body can prevent corrosion and contamination, which is very important for food-grade oil production.

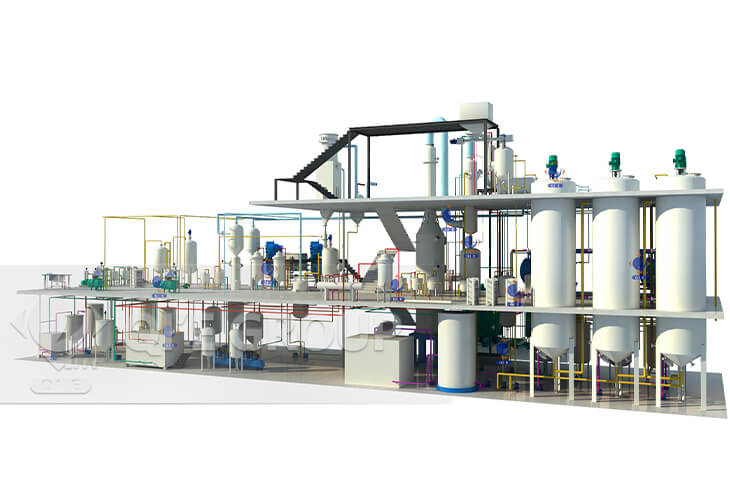

Large-scale production enterprises require high-capacity equipment with full-automatic continuous operation processes. These machines are designed to handle large amounts of raw materials, with a daily processing capacity of more than 5 tons. They can achieve high efficiency and stability in continuous operation.

In addition to high capacity, energy-saving optimization is also a key consideration. For example, some large-scale presses use low-energy motors and intelligent control systems to reduce energy consumption. The oil output rate can reach up to 50%. The energy consumption per ton of raw materials can be significantly reduced compared to small and medium-sized machines. The fully automatic operation also reduces labor costs and human errors.

Throughout the entire sunflower oil processing process, there are many technical highlights. For example, efficient shelling can significantly improve the oil output rate. By removing the shells before pressing, the contact area between the kernels and the press is increased, which allows for more efficient oil extraction. Stainless steel materials play an important role in ensuring hygiene and safety. They are resistant to corrosion and easy to clean, which is crucial for food processing industries.

The filtration accuracy also has a direct impact on the purity of the oil. High-precision filters can remove impurities and ensure the quality of the final product. Different levels of filtration can be selected according to different production requirements.

The sunflower oil screw press industry is constantly evolving. New technologies such as intelligent control, low-energy motors, and remote monitoring are being increasingly applied. Intelligent control systems can automatically adjust the operating parameters according to the raw material characteristics and production requirements, which improves the production efficiency and reduces energy consumption. Low-energy motors can save a large amount of electricity costs in the long run. Remote monitoring allows operators to monitor the operation status of the equipment in real-time and make timely adjustments, even from a distance.

In conclusion, whether you are a small-scale processing plant, a medium-scale processing plant, or a large-scale production enterprise, there is a suitable sunflower oil screw press for you. By understanding the characteristics and requirements of different scale users, and considering the technical highlights and industry trends, you can make a more informed decision.

Ready to understand the right automation level for you and get a customized pressing solution?