As global demand for vegetable oils continues to rise, manufacturers are seeking efficient and reliable methods to maximize oil yield while maintaining quality. The hot press sunflower seed oil expeller has emerged as a key solution in large-scale commercial production. By leveraging advanced thermal processing techniques, this equipment significantly improves oil extraction efficiency, offering substantial economic benefits to businesses.

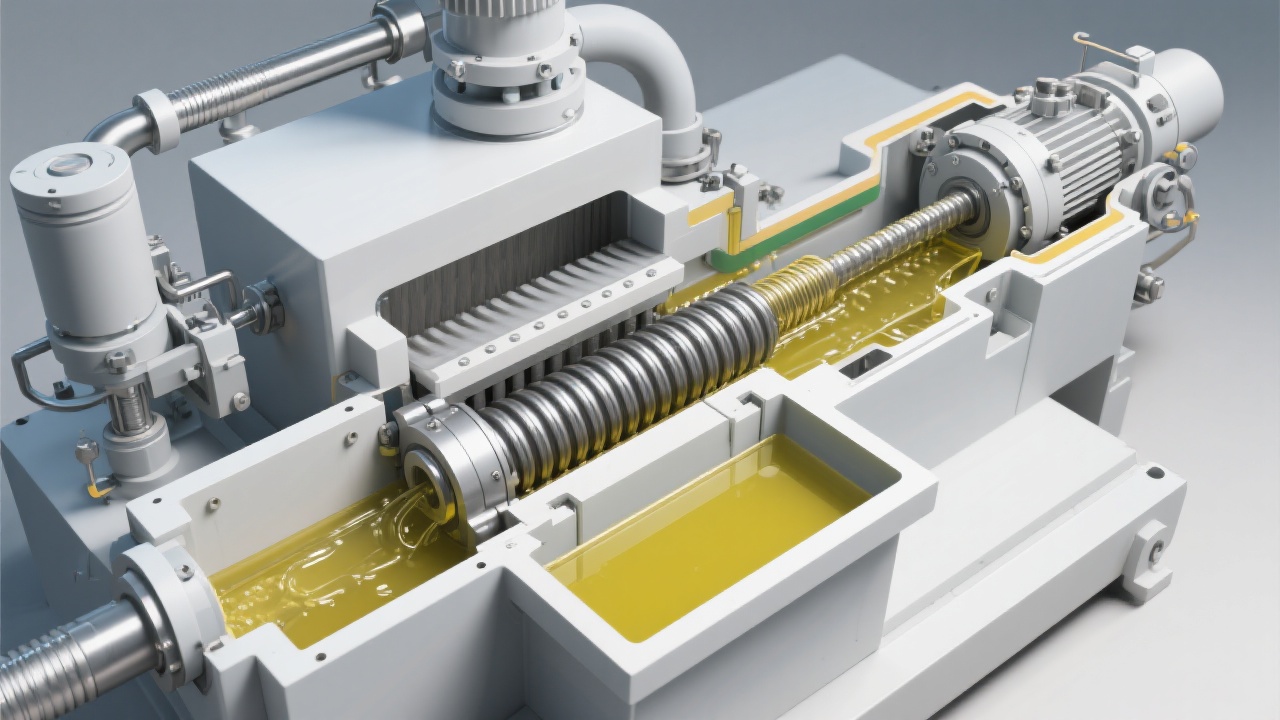

The hot press sunflower seed oil expeller operates by applying heat and pressure to the raw seeds, which softens the cell walls and facilitates oil release. This process is more effective than traditional cold pressing methods, as it reduces the viscosity of the oil, allowing it to flow more freely from the seeds. According to industry data, hot press technology can increase oil yield by up to 15% compared to cold pressing, depending on seed quality and operating conditions.

While cold pressing preserves more natural nutrients, it often results in lower oil yields due to the higher viscosity of the oil at lower temperatures. In contrast, hot press technology optimizes the physical properties of the oil, leading to improved extraction rates. For example, a study conducted in 2023 found that using a hot press system increased oil recovery from 42% to 48% in a typical sunflower seed processing plant.

| Processing Method | Oil Yield (%) | Energy Consumption (kWh/ton) |

|---|---|---|

| Cold Press | 42 | 180 |

| Hot Press | 48 | 210 |

One of the primary concerns when using hot press technology is maintaining oil quality. However, modern systems are designed with precise temperature control mechanisms to ensure optimal performance without compromising the nutritional value or flavor of the oil. By maintaining a consistent temperature between 100°C and 130°C, manufacturers can achieve high oil yield while preserving key components such as vitamins and antioxidants.

A major sunflower seed processing company in Eastern Europe implemented a hot press system in 2022. After one year of operation, they reported a 17% increase in daily oil output and a 12% reduction in energy costs per ton of processed seeds. The company also noted improved consistency in oil quality, which helped them secure long-term contracts with international buyers.

To fully leverage the benefits of a hot press sunflower seed oil expeller, operators should follow these best practices:

The integration of hot press technology into commercial sunflower seed oil production not only boosts oil yield but also enhances operational efficiency and cost-effectiveness. As the global market demands higher productivity and sustainable practices, adopting advanced equipment like the hot press sunflower seed oil expeller becomes a strategic advantage for manufacturers.

Ready to transform your oil production? Discover how our high-performance hot press systems can help you achieve greater output and profitability. Explore Our Solutions Now.