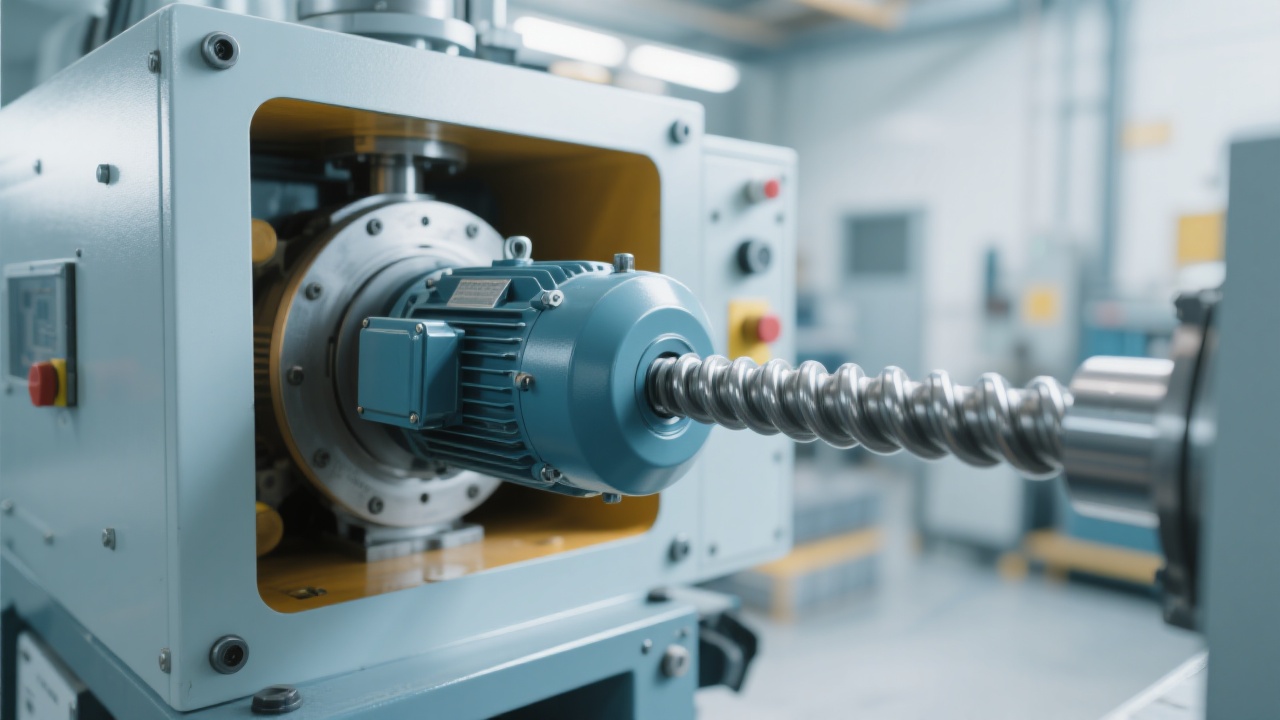

In today's competitive global market, the demand for high-quality sunflower seed oil has surged, especially within export sectors that emphasize purity, taste, and health benefits. However, traditional extraction methods often fall short in meeting these stringent quality standards and tend to be labor-intensive and time-consuming. Integrated (one-step) sunflower seed oil press machines, featuring innovative oil filtration systems that combine extraction and filtration seamlessly, are transforming the industry by enhancing oil quality while significantly boosting production efficiency.

The defining characteristic of these advanced machines lies in their integrated filtration design, allowing the pressing and filtering of sunflower seed oil to occur simultaneously. This one-step process replaces the traditional multi-phase methods, which typically involve separate steps for extraction, settling, and filtration, reducing operational complexity. The built-in system ensures that impurities such as seed residues, waxes, and other particles are removed instantly during pressing, producing cleaner oil straight from the machine.

Key Product Highlights:

The integrated filtration system operates on a principle of continuous separation, wherein centrifugal force or fine mesh filters trap solid particles immediately as oil is expelled. This reduces oil oxidation and contamination risks, which are common in batch filtration methods. Studies indicate these systems can improve oil purity by up to 30% compared to traditional presses, with filtration rates exceeding 90% efficiency.

By minimizing oil exposure to air and mechanical handling, the integrated system preserves the natural antioxidants and flavor compounds that define premium sunflower seed oil quality — a critical factor for export markets demanding stringent quality certification such as ISO 22000 and HACCP compliance.

| Benefit | Impact |

|---|---|

| Process Simplification | Combines pressing and filtering, reducing production steps by 40%. |

| Time Efficiency | Increases throughput by up to 25%, enabling faster order fulfillment. |

| Oil Quality Enhancement | Results in clearer oil with lower sediment content, improving shelf life and marketability. |

| User-Friendly Operation | Requires less manual labor and technical skill, suitable for diverse users. |

The design flexibility of integrated sunflower seed oil presses makes them ideal not only for small artisanal producers but also for family-operated setups and expanding SMEs aiming to break into export markets. Their compact footprint and relatively low power consumption further enhance appeal for rural areas with limited infrastructure.

Given their modular construction, these machines can adapt across various scales—processing from 50 kg to several hundred kilograms of seeds per hour—offering scalability without compromising oil integrity or consistency.

“Since adopting the integrated press, our oil clarity and flavor consistency have noticeably improved, allowing us to gain new international clients. Production time has decreased by nearly one-third, drastically cutting operational costs.” — SunOil Export Ltd., CEO

Such testimonials underscore how one machine can decisively reposition producers within the competitive export landscape, enabling compliance with international quality norms and enhancing brand reputation.

What challenges have you faced with traditional oil pressing methods? How do you see integrated filtration technology influencing your production workflow? We invite industry professionals and enthusiasts to exchange ideas and insights in the comments section below. Your feedback helps drive continuous innovation and adoption of high-performance sunflower seed oil production solutions.