Sunflower oil is prone to rancidity during storage or processing due to oxidation, metal residues, and microbial contamination, which seriously affects its quality and safety. This tutorial comprehensively analyzes the key quality control points in the entire process from raw material cleaning to airtight filling, with a focus on how the vacuum deodorization process effectively removes odors and reduces free fatty acids, and how it combines with airtight packaging technology to prevent oxygen intrusion, fundamentally avoiding oil rancidity.

From raw material treatment to final packaging, every step in the production of sunflower oil can influence its quality. For example, during the raw material stage, the presence of iron filings in sunflower seeds can act as a catalyst for oxidation, accelerating the rancidity process. High moisture content in the seeds can also provide a breeding ground for microorganisms, leading to spoilage.

During the processing stage, prolonged exposure to air can cause the oil to oxidize. Even a small amount of air contact can gradually change the chemical composition of the oil, resulting in an unpleasant odor and reduced nutritional value. Additionally, improper temperature control during refining can also lead to the degradation of the oil's quality.

As mentioned earlier, iron residues are a significant risk factor. Iron can react with oxygen in the oil, forming free radicals that initiate the oxidation process. The moisture content is another critical factor. When the moisture in the oil exceeds 0.1%, it can promote the growth of mold and bacteria, which produce enzymes that break down the oil into free fatty acids and glycerol, causing rancidity.

Excessive air contact is also a major culprit. Once the oil is exposed to air, the unsaturated fatty acids in the sunflower oil react with oxygen, forming peroxides, which then decompose into aldehydes, ketones, and other substances with unpleasant odors.

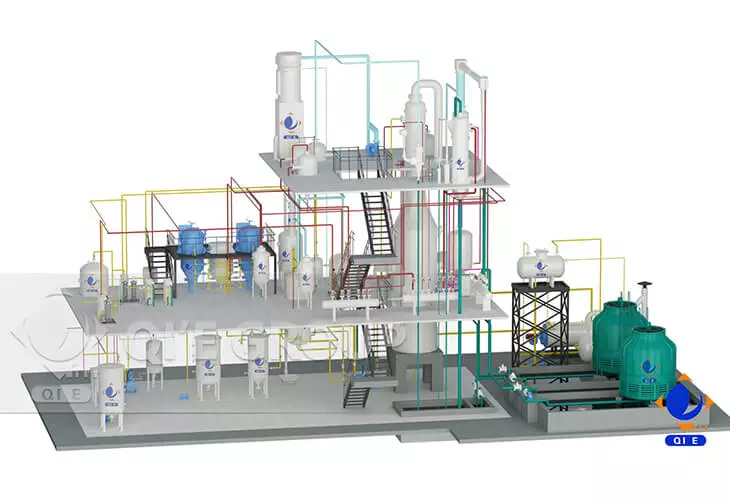

Vacuum deodorization is a key step in the refining process of sunflower oil. Under vacuum conditions, the boiling point of volatile substances in the oil is significantly reduced. By heating the oil to about 200 - 240°C under a vacuum of 2 - 4 mbar, free fatty acids, odor - causing substances, and some harmful substances can be effectively removed. Our vacuum deodorization equipment can reduce the acid value of the oil to ≤0.5mg KOH/g, greatly improving the stability and flavor of the oil.

Airtight packaging technology is equally important. By using high - barrier packaging materials such as PET bottles with oxygen - absorbing liners or aluminum - foil laminated bags, the intrusion of oxygen can be effectively blocked. This extends the shelf - life of the oil from an average of 6 months to over 12 months, ensuring that the oil remains fresh and of high quality for a longer time.

Adhering to food industry standards such as ISO 22000 and HACCP is crucial for ensuring the quality and safety of sunflower oil. These standards provide a systematic approach to identifying and controlling hazards at every stage of production.

According to a real - world example from a leading sunflower oil manufacturer, after implementing the vacuum deodorization and airtight packaging technologies in strict accordance with HACCP standards, the rejection rate of their products due to rancidity decreased from 5% to less than 1%. This not only saved production costs but also enhanced their market competitiveness.

"By integrating these advanced technologies and industry standards, we can build a scientific quality control system, enhancing the stability of sunflower oil products and their market competitiveness." - An experienced food engineer

Are you looking to improve the quality and shelf - life of your sunflower oil products? Our advanced vacuum deodorization and airtight packaging solutions can help you achieve these goals. Click here to learn more about our technologies and take your sunflower oil production to the next level!