Sunflower oil is a popular cooking oil known for its light flavor and high nutritional value. However, many production enterprises often face the problem of odor generation during storage. This not only affects the taste of the oil but may also pose potential food safety risks. The causes of this issue are multifaceted, involving every step from raw material procurement to the final packaging.

Firstly, the cleanliness of raw materials plays a crucial role. Impurities in sunflower seeds, such as dust, debris, and mold, can introduce unwanted flavors into the oil during the extraction process. For example, moldy sunflower seeds may contain mycotoxins, which not only affect the taste but also pose health risks. Secondly, the choice of pressing method can also impact the oil's quality. Cold - pressing generally retains more nutrients but may have a shorter shelf - life and be more prone to odor development compared to hot - pressing. However, hot - pressing at excessive temperatures can cause the oil to undergo thermal decomposition, resulting in the formation of off - flavors.

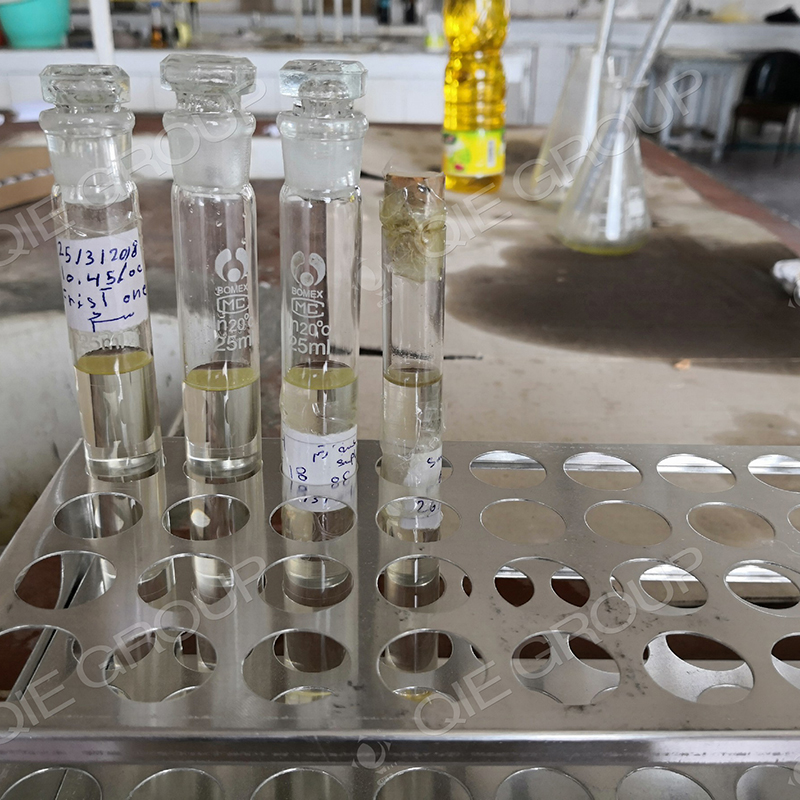

The filtration accuracy is another key factor. Insufficient filtration may leave behind small particles and impurities, which can act as catalysts for oxidation and spoilage over time. In addition, the degree of refining affects the oil's stability. A well - refined oil with a low level of free fatty acids and other impurities is less likely to develop an unpleasant odor. Finally, the hygiene during the filling process is essential. Any contamination during filling, such as improper cleaning of containers or exposure to air, can accelerate the oxidation of the oil and lead to odor formation.

The vacuum deodorization process is a critical step in improving the quality and stability of sunflower oil. It works by removing volatile odor - causing substances under reduced pressure conditions. Under vacuum, the boiling point of these volatile compounds is significantly lowered, allowing them to be removed at relatively low temperatures without causing thermal damage to the oil.

This process is particularly effective in reducing the levels of free fatty acids and other odor - causing substances. For instance, it can reduce the free fatty acid content in sunflower oil from an average of 0.5% to less than 0.1%, greatly enhancing the oil's flavor and shelf - life. The key implementation points of the vacuum deodorization process include proper temperature control, vacuum level adjustment, and the duration of the process. Generally, the deodorization temperature is maintained between 200 - 240°C under a vacuum of 1 - 5 mmHg for about 30 - 60 minutes.

According to the HACCP (Hazard Analysis and Critical Control Points) standard, the vacuum deodorization process is a critical control point in the production of high - quality sunflower oil. It helps to ensure that potential hazards related to odor and spoilage are effectively controlled.

Compliance with industry standards such as ISO 22000 is essential for sunflower oil production enterprises. ISO 22000 provides a framework for food safety management, covering all aspects from raw material sourcing to product delivery. By adhering to these standards, enterprises can ensure the consistency and safety of their products.

Let's take a look at a practical case from a leading sunflower oil production plant. Before implementing the vacuum deodorization process, they received an average of 10 customer complaints per month regarding oil odor. After adopting the process and strictly following the ISO 22000 standard, the number of complaints dropped to zero within three months. This shows the significant impact of the vacuum deodorization process and quality management on product quality and customer satisfaction.

To better understand the impact of different processing stages on the final flavor of sunflower oil, we can use comparison diagrams or flowcharts. These visual tools can clearly show how each step, from raw material processing to refining and deodorization, affects the oil's flavor profile. For example, a flowchart can illustrate how the removal of impurities and odor - causing substances at each stage leads to a purer and more stable oil.

It's important to note that while the vacuum deodorization process is a powerful tool, a comprehensive quality management system is needed for long - term success. Our oil refinery machines come standard with a vacuum deodorization module, which has helped many customers achieve zero odor complaints. By focusing on building a complete quality management system that encompasses all aspects of production, from raw material control to post - production storage, enterprises can enhance the stability and market competitiveness of their sunflower oil products.

Do you have any experience or questions about sunflower oil quality control? Feel free to leave a comment below and share your thoughts! Click here to learn more about our oil refinery machines with vacuum deodorization modules.