In the global market of sunflower oil exports, ensuring high - quality products is crucial for enterprises to gain a competitive edge. This article delves into the entire production chain of sunflower oil, highlighting the significance of aseptic filling technology as the final quality barrier.

The quality of sunflower oil is affected at every stage of the production chain. Starting from raw material cleaning, impurities such as dirt, stones, and metal residues can be present in sunflower seeds. Metal residues, for example, not only affect the taste but also pose a potential health risk. According to industry data, about 5 - 10% of raw sunflower seeds may contain some form of metal impurities. To address this, advanced magnetic separators can be used to remove these metal particles, ensuring the purity of the raw materials.

During the pressing process, the choice of pressing technology is crucial. Cold - pressing technology can retain more nutrients in sunflower oil, such as vitamin E and unsaturated fatty acids. However, it may have a lower oil yield compared to hot - pressing. On average, cold - pressing can achieve an oil yield of about 30 - 35%, while hot - pressing can reach 38 - 42%. Yet, hot - pressing may cause some oxidation of the oil, leading to a shorter shelf - life and potential generation of unpleasant odors.

Aseptic filling is the last and most critical step in ensuring the quality of sunflower oil for export. It acts as a strong barrier against microbial contamination. By using a fully automated aseptic filling system, the risk of microbial contamination can be reduced by up to 99%. This is an essential configuration for obtaining export certifications.

One of the key functions of aseptic filling is to prevent oxidation and the generation of off - flavors. In traditional filling methods, exposure to air can cause the oil to oxidize rapidly, especially when exposed to light and heat. Aseptic filling isolates the oil from the external environment, effectively extending the product's shelf - life. Industry statistics show that sunflower oil filled using aseptic technology can have a shelf - life that is 2 - 3 times longer than that filled using non - aseptic methods.

To ensure the quality and safety of sunflower oil, industry standards such as ISO 22000 and HACCP are widely adopted. These standards cover all aspects of the production process, from raw material sourcing to final product packaging. For example, a well - known sunflower oil export enterprise in [Country Name] implemented HACCP - based quality control measures in its production process. By strictly following these standards, especially in the aseptic filling stage, they were able to significantly reduce product recalls and improve customer satisfaction.

"In our experience, aseptic filling is the key to ensuring the long - term stability of sunflower oil quality. It not only meets international quality requirements but also enhances the brand image in the global market." - An experienced engineer in the sunflower oil industry.

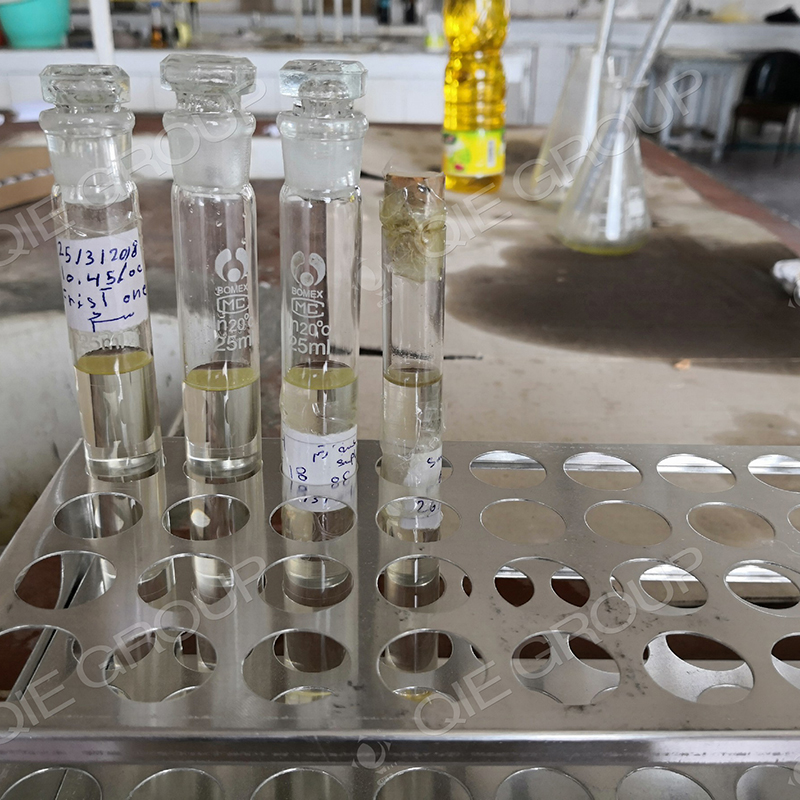

Visualizing the pollution source control logic can help enterprises better understand and manage the production process. A flowchart showing the process from iron filings in raw materials, through filtration, to aseptic filling can clearly illustrate the closed - loop management of pollution sources. This kind of visual representation can improve the efficiency of quality control and reduce the risk of human error.

Aseptic filling technology enables sunflower oil to meet overseas regulations more easily. Many countries have strict requirements for food safety and quality, especially regarding microbial content and shelf - life. By using aseptic filling, enterprises can ensure that their products meet these requirements, opening up more opportunities in the international market. Moreover, products filled aseptically can command a higher price in the market, enhancing the brand's premium ability. On average, aseptically filled sunflower oil can be sold at a price that is 15 - 20% higher than non - aseptically filled products.

In conclusion, aseptic filling technology is an indispensable part of the sunflower oil export process. It not only ensures product quality but also brings significant export advantages. If you are an export - oriented oil enterprise looking to enhance your product quality and gain international trust, explore our advanced aseptic filling solutions now.